Cleanroom Equipments

Cleanroom Equipment restrict cross contamination, provide a safe and comfortable position for the operator and most importantly ensure that the Clean room system maintains its parameters.

Pass Box

In pharmaceuticals manufacturing facilities, it is essential to minimize man/material movement and avoid cross-contamination between different classified areas to achieve the desired classification and to maintain the integrity of products and processes. Pass Box is designed to allow material transfer without much personnel movement. It also aids in controlling the ingress of particulate contaminants into clean rooms and between different classified areas.

Air Shower

Air shower is a self-contained air chamber installed at the entrance to cleanrooms in order to minimize the amount of particulate contaminants entering the cleanroom. Personnel move through the air shower while particulate contaminants are washed off with high-velocity HEPA-filtered air jets. The high air velocity of 6000 FPM ensures efficient scrubbing action necessary to remove particulate matter. Contaminated air is then taken in through the base of the unit, filtered, and re-circulated into the chamber.

Laminar Air Flow Unit

LAF is designed for offering the highest product protection for samples and processes by providing ISO class 5 particle-free work station. LAF offers proven protection for samples and processes. The work station is continuously supplied with positive pressure HEPA filtered vertical air flow. The vertical unidirectional airflow speed prevents contamination from the operator and environment to work station. The laminarity of the flow prevents cross-contamination between the items handled in the working space. LAF is available in powder-coated G.I steel, S.S.316, S.S.316 L, or a combination of both.

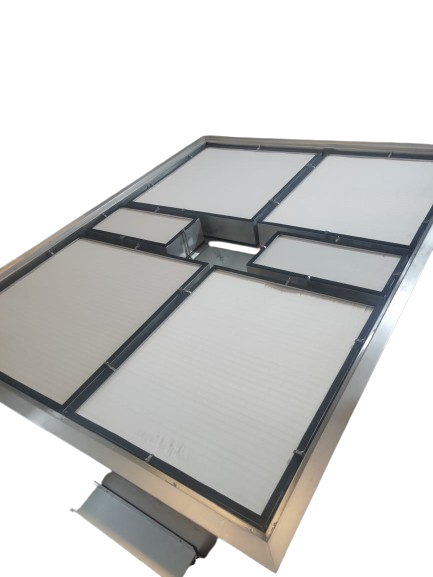

OT Plenum Laminar Air Flow

OT Plenum LAF is designed for offering the highest product protection for samples and processes by providing ISO class 5 particle-free work station. LAF offers proven protection for samples and processes. The work station is continuously supplied with positive pressure HEPA filtered vertical air flow. The vertical unidirectional airflow speed prevents contamination from the operator and environment to work station. The laminarity of the flow prevents cross-contamination between the items handled in the working space. LAF is available in powder-coated G.I steel, S.S.316, S.S.316 L, or a combination of both.

Cleanroom Clothing

People who work in cleanrooms undergo extensive training to maintain the cleaning standards. They enter and exit the cleanroom through by wearing special clothes designed to trap contaminants which are shed by the bodies of people working in the clean rooms. Depending on the complexity & classification of clean room, cleanroom clothing could be as extensive as fully covered in multiple layered dresses with self-contained breathing apparatus. Cleanroom clothing is used to prevent microbes, particles from being released off the wearer’s body and contaminating the environment. The cleanroom clothing must not release any kind of particles or fibers to prevent contamination of the environment. So much so is the importance of clean room clothing, that in case if the same is not being maintained, it can certainly degrade the performance of semiconductors and can lead to cross-infection between patients and healthy people in Pharmaceuticals or Medical Industries.